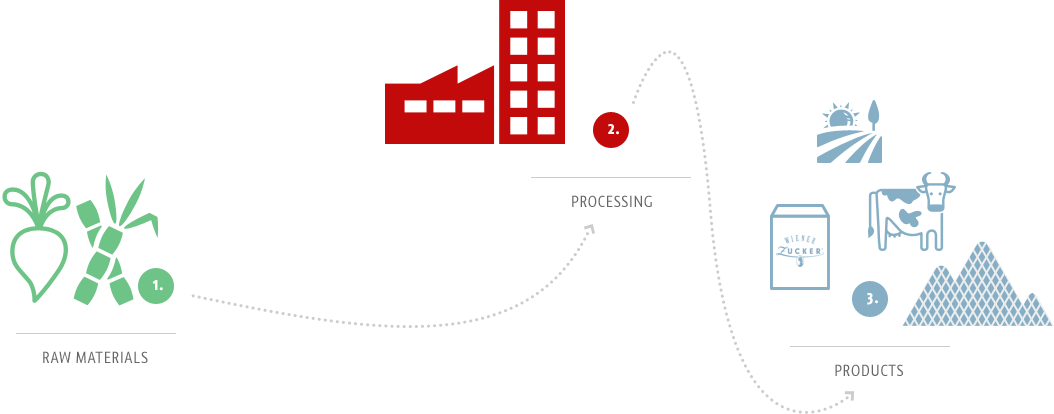

In the 2022|23 financial year, we processed 4.7 million tonnes of sugar beet procured from contract growers based in the EU. Contractual farming enables close cooperation with our suppliers, ensuring and documenting the use of good agricultural practices as well as fair working conditions, which we ascribe to in our general principles for the procurement of agricultural raw materials and intermediate products.

Awareness-building activities in 2022|23 remained limited to events held in small groups and to virtual offerings under the “AGRANA4You” advisory programme. For example, subject-specific webinars were offered again for beet growers, focusing on the topics of planting, seed, and crop protection for the 2022 season.

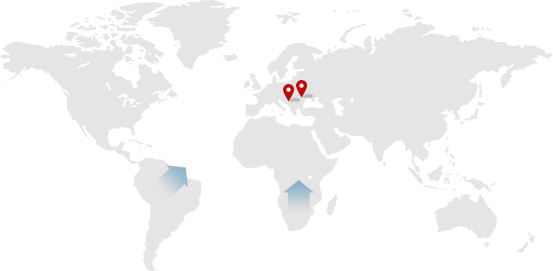

In the Sugar segment, the contract beet suppliers in all five beet production countries have been grouped into so-called Farm Management Groups (FMGs). In 2017, these groups’ sustainability performance had been externally audited in accordance with FSA requirements for the first time, and the re-verification audits took place in 2020. In the groups in Austria and the Czech Republic, 100% of the farms achieved at least FSA Silver status. In Romania, Slovakia and Hungary, the audits could only be completed in 2021 due to travel and contact restrictions amid the Covid-19 pandemic. As in the initial audit in 2017, all Slovak farms achieved at least FSA Silver status. The FMG in Hungary successfully improved its results compared to the first audit, so that here too, all growers obtained at least FSA Silver standing. Romania also showed an improvement in audit results, with 60% of farms achieving an FSA Silver rating, although the target of 100% FSA Silver was not attained. For the current, 2023|24 financial year, a re-verification under the new FSA 3.0 standard is planned.

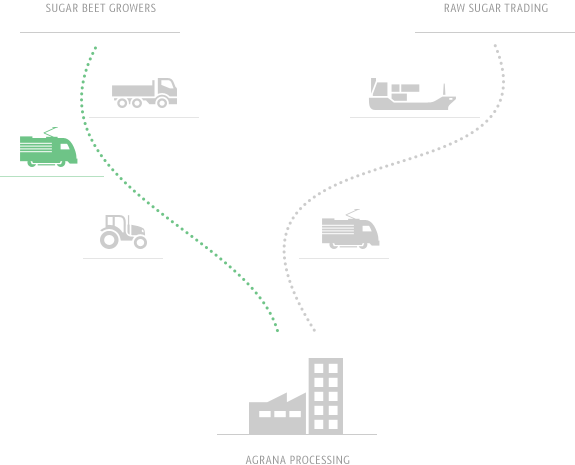

We produce sugar by refining raw sugar from sugar cane at a number of our production sites in the Sugar segment. We procure this raw sugar from traders from least developed countries (LDC), or from Brazil.

In the 2022|23 processing season, an average of around 35 % of the beet was delivered to the sugar factories by rail. This was highest Austria and in Hungary at around 49 % and 48 %, respectively.

As an energy-intensive processor of agricultural raw materials, we strive to optimise our energy consumption and efficiency, as well as to reduce our emissions on an ongoing basis. In order to achieve these objectives, we are integrating an energy management system, based on standards such as ISO 50001, into our existing quality management system. In 2022|23 the energy management systems of 100 % of the Sugar segment’s production sites held a current ISO 50001 certification.

Natural gasIn the 2022|23 financial year, we met approximately 57 % of our total energy needs with natural gas, 14 % with coal and coke, 4 % with steam, 6 % with renewable energy sources (e.g.biogas, biomass and electricity), and the rest with other energy sources. To avoid a potential natural gas supply shortfall during the 2022|23 beet processing campaign, a supply of extra light heating oil (ELHO) was contractually secured immediately after the outbreak of the war in Ukraine to ensure continuity of production under any circumstances. Ultimately, about 18,300 tonnes of ELHO (15% of energy consumption) were used.

New technologiesWith the installation of low-temperature dryers in sugar factories in Austria in 2011|12, which capture waste heat from earlier process steps and harness it for the drying of desugared beet pulp to produce animal feed, we have since saved emissions of about 30,000 tonnes of CO2 annually.

Increasing the share of energy provided on site with biogasThe Kaposvar sugar plant in Hungary generated about 18.91 million cubic metres of biogas from beet pulp in the 2022|23 financial year. This would have been sufficient to cover approximately 88 % of the site’s primary energy requirement for the 2022|23 beet campaign. About 9.7 million cubic metres of the biogas produced at the facility (containing about 55 % methane) were refined by the biogas upgrading plant installed in autumn 2015 into biomethane (100 % methane) for feeding into the local natural gas grid. The biomethane injected into the grid was equivalent to the annual heating requirement of about 1,919 single-family homes.

AGRANA Climate StrategyAGRANA is committed to the goal of CO2-neutral production by 2040. This challenging target can only be achieved by a politically and societally supported mix of measures in several steps. The possible measures fall into two main categories: energy efficiency improvements, and the switch to renewable energy sources.In the future, low-protein raw material residues will be used to generate energy and replace fossil energy sources, as in AGRANA’s Hungarian sugar factory in Kaposvar.

Continuously improving our specific energy consumption thanks to our energy management systemIn the Sugar segment, in order to support AGRANA’s climate strategy, a target is currently being developed to meet the requirements of the Science Based Targets initiative.

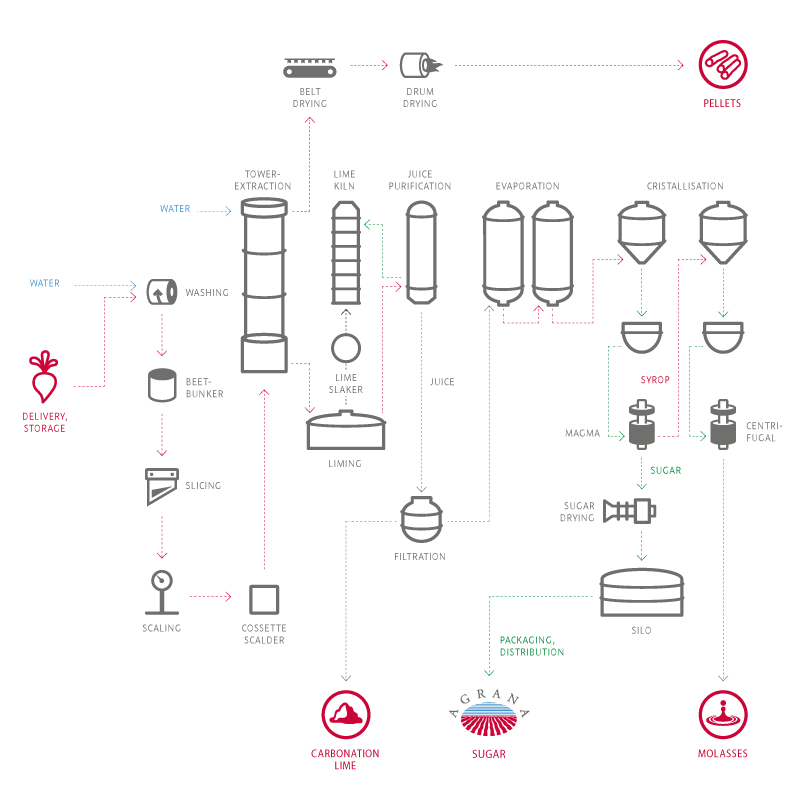

The water we require during production is brought in part to the factory with the sugar beet. Sugar beet is made up of approx. 75 % water, which needs to be separated from the sugar during the production process. This water is used both for extracting the sugar from the beet pulp and for transporting and cleaning the beet. The water is cleaned and reused time and again. Overall, a sugar factory discharges more water than it withdraws and thus has a negative water consumption balance.

On-site or external waste water treatment plants ensure that the waste water produced is treated in an environmentally sensitive way in accordance with local thresholds.

| Sugar segment | 2022 | 23 |

|---|---|

| Water withdrawal in m3 per tonne of core and by-products | 2.29 |

| Water discharges in m3 per tonne of core and by-products | 3.06 |

| Water consumption in m3 per tonne of core and by-products | (0.77) |

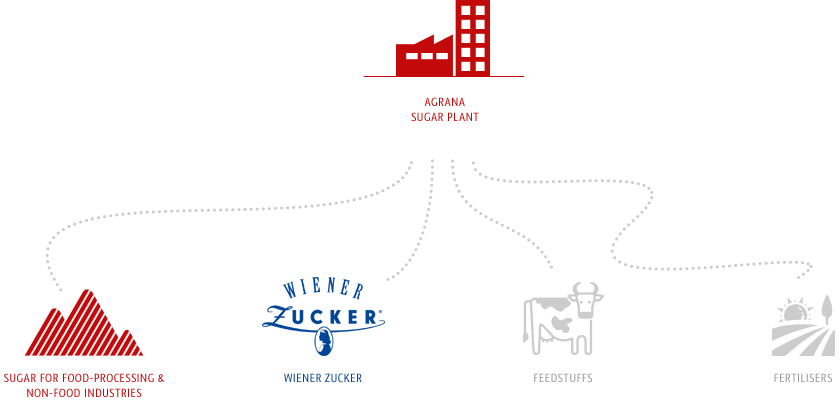

It is our operating principle to maximise the utilisation of agricultural raw materials by making valuable by-products, contributing to our economic and social bottom line.

In the Sugar segment, we produce a tonne of by-products for every tonne of sugar. These make an important economic contribution while, at the same time, fulfilling an environmental function.

Given that they are largely used as fertilisers and feedstuffs for animals, they close the material cycle by returning minerals and other nutrients to the land and the food chain.

| Sugar segment | 2022 | 23 in tonnes |

|---|---|

| Waste disposed | 14,689 |

| of which hazardous waste | 105 |

| Kilogramme waste per tonne of product | 7.2 kg |

| Gramme hazardous waste per tonne of product | 51 g |

An average of 1,935 employees (headcount) worked in our Sugar segment during the 2022|23 financial year. They are a key factor for success due to their commitment, range of skills, experience and views.

Even in a challenging economic environment, AGRANA endeavours to offer interesting work, opportunities for professional and personal development and training, and a workplace environment in which employees feel integrated, respected and connected.

Non-permanent staff

164

30.5 %

Permanent staff

1,681

27.2 %

Blue-collar979

16.6 %

White collar702

42.0 %

Managers

155

31.6 %

Of which Executive Leadership

15

26.7 %

Total

Female

At the end of the day, it is important that all of our employees return home safely. We strive to achieve this objective by means of regular trainings on safe working processes, implementing best practice cases and providing workplace safety materials as part of our zero-accident policy.

In the 2013|14 financial year, we have started to collect workplace safety data across all business segments by means of uniform worldwide criteria.

Injury rate 22 | 23(number of accidents/ 100 employees p.a.)

2.3

2.0

2.5

Rate of high-consequence injuries 22 | 23(high-consequence injuries/ 100 employees p.a.)

0.0

0.0

0.0

Rate of fatalities 22 | 23(fatalities/ 100 employees p.a.)

0.0

0.0

0.0

Total

Female

Male

In the 2021|22 financial year, we revised the AGRANA Code of Conduct, which establishes minimum (social) standards and rules of conduct for all employees around the world.

As part of our membership of SEDEX , which we have had since 2009, our production sites perform a SEDEX self-assessment every year. In order to underpin our commitment, we had a 4-pillar SMETA audit valid for three years at 88.9 % of our production sites conducted by independent third parties since 2020. The audit reports can be accessed by SEDEX members on the organisation’s online platform.

The education and training, as well as the personal development, of our employees is important to us. Employees in the Sugar segment completed an average of 19.1 training hours in the 2022|23 financial year. In total, 98.2 % of employees completed a training course.

In the 2020|21 financial year, AGRANA Zucker GmbH again updated its sustainability data reported annually since 2014 for the purposes of EcoVadis, the international supplier evaluation platform. The assessment resulted in a Silver rating for AGRANA Zucker GmbH.

We use cookies and analysis software to make our website as user-friendly as possible. By clicking on "Accept all", you agree to the use of all cookies. You can change your cookie settings at any time. You can find more information in our privacy policy.

Cookies of this category are necessary for the basic functions of the website and therefore cannot be deactivated.

Cookies in this category enable us to analyze website usage and measure performance.