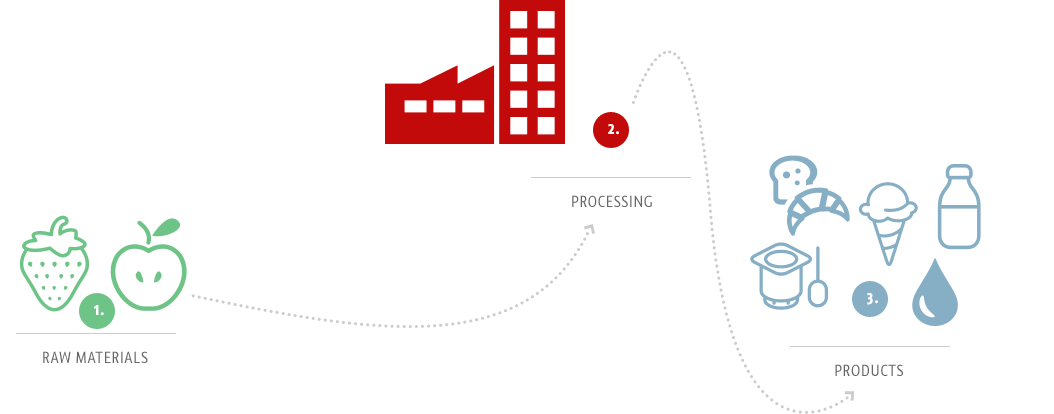

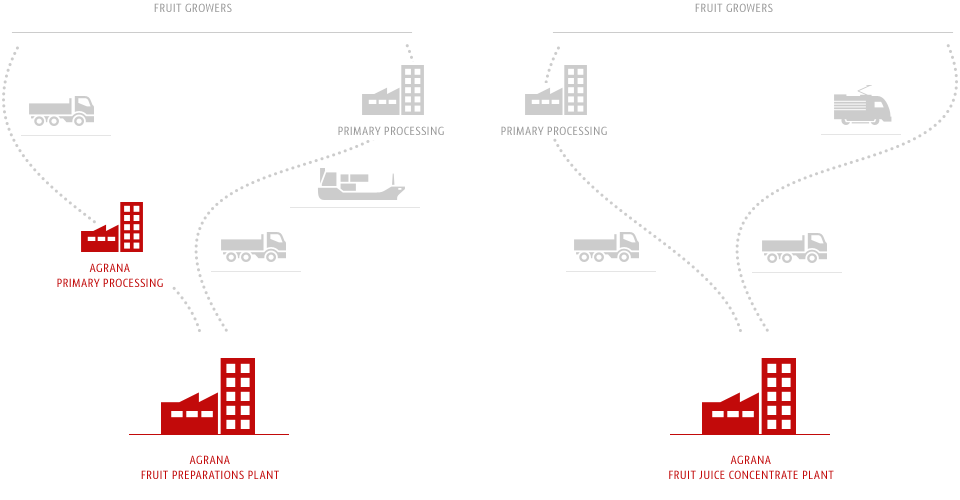

The fruit used in our fruit preparations is sourced largely from primary processors or traders in the form of intermediate products (i.e. fruit in a frozen or aseptic form, purees). As part of our principles for procuring agricultural raw materials, we have defined international standards that, if complied with, we accept as proof of sustainability. In the 2022|23 financial year, 20.8% (prior year: 17.4%) of the raw materials (fruits and other ingredients) procured by the purchasing organisation, AGRANA Fruit Services GmbH, for the fruit preparations segment had a valid sustainability certification as defined in the AGRANA principles for the procurement of agricultural raw materials and intermediate products. Of the fruit processed worldwide, 13.9% had a sustainability certification (prior year: 6.1%). Most of this represented an FSA certification of at least Silver level, or an equivalent certification under an international standard. The target under the Strategy 2025|26 of the fruit preparations business is to increase the proportion of processed fruit with a sustainability certification to 26%. To evaluate its suppliers for their adherence to social criteria, AGRANA Fruit Services invites new suppliers to participate in the Supplier Ethical Data Exchange, or SEDEX. At the end of the financial year, the fruit preparations business had SEDEX data (and audit documents where applicable) for about 75% of the processed volume of raw materials (prior year: 72.2%). By 2025|26, the fruit preparations business plans to receive valid SEDEX data for supplier evaluation for at least 90% of the fruit volume processed each year.

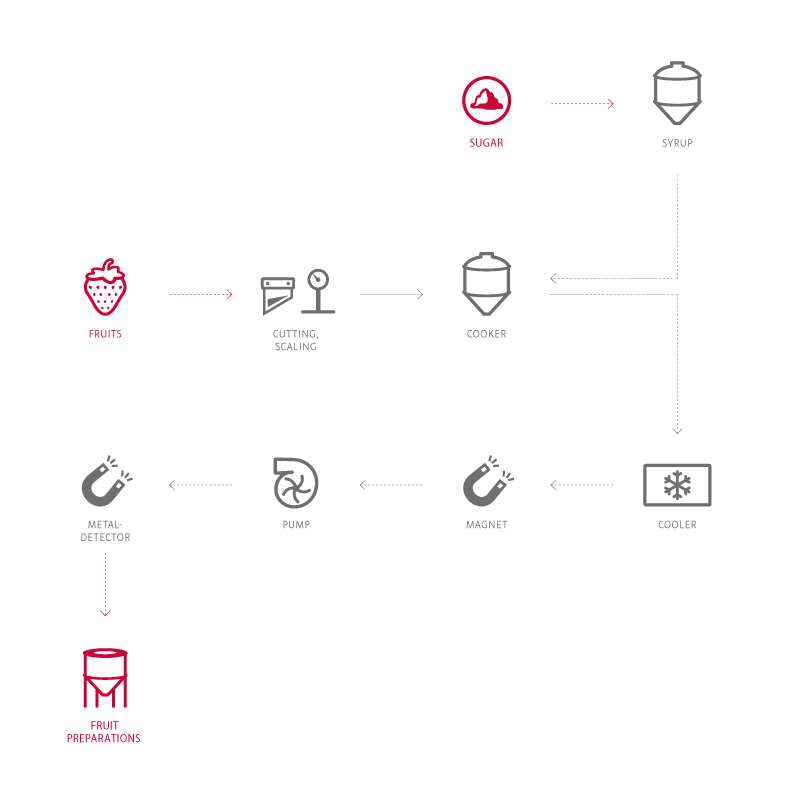

We acquire around 20% of fruit used in the preparations in the form of fresh fruit from contract growers. These are then washed, cleaned, chopped and frozen at our own primary processing plants in Mexico, Morocco, Poland and the Ukraine for them then to be processed into fruit preparations.

In the course of sourcing from contract growers, we work closely together with our fruit suppliers, for example in Mexico in qualification and certification projects.

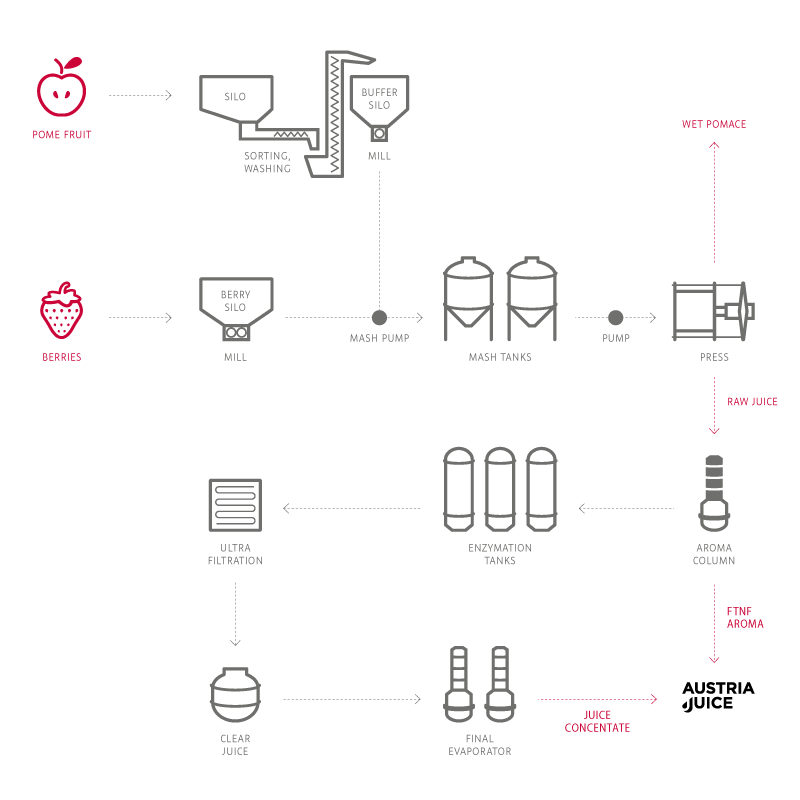

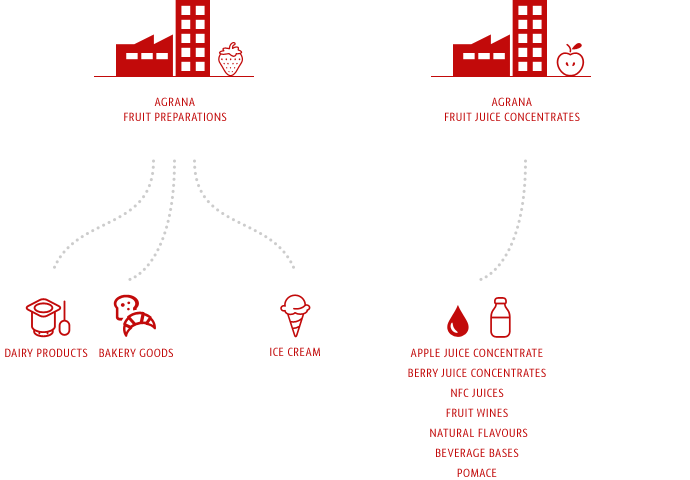

In the fruit juice concentrate business, we process apples and berries in Europe and in a plant in China. We primarily acquire our raw materials via collection points from dealers. In 2018|19, AUSTRIA JUICE joined the Sustainable Juice Covenant, a global initiative aimed at making the procurement, production and marketing of fruit- and vegetable-based juices, purees and concentrates 100% sustainable by the year 2030.

In the 2021|22 financial year, for harvest reasons, only about 11% of total apple supplies processed came from two projects launched in Hungary and Poland in 2000 to grow resistant types of apples, which require the use of 60% less pesticide. At the start of the project, the growers received financial support planting new trees and have since been receiving advice during the whole growing season and guaranteed purchases.

In the 2020|21 financial year, Hungarian suppliers of disease- and pest-resistant apple varieties, who were selected according to SAI standards, again participated in the mandatory completion of the FSA questionnaire and the external audits. Hungarian contract growers of sour cherries, elderberries and carrots also participated in the FSA verification system. AUSTRIA JUICE is entitled to claim FSA Silver (and in some cases Gold) status for three years for Hungarian growers for all raw material categories mentioned. In 2018|19 the FSA questionnaire and external verification were also used for the contract growers of resistant apple varieties in Poland. In 2021|22, the Polish supplier farms for resistant apple varieties, as well as other direct suppliers of apples and various berries, were re-verified or verified. Based on the results, AUSTRIA JUICE has been able to advertise at least FSA Silver level for all Polish contract growers of resistant varieties. As well, FSA silver status equivalent can be claimed under the benchmarking of the FSA requirements against the national legislation of, for example, Poland, Spain and Hungary, when combined with a certification to the Global GAP standard. In total, AUSTRIA JUICE in 2022|23 was thus able to claim FSA silver or higher status for about 33% of its raw material processing volume.

As a processor of agricultural raw materials, we strive to optimise our energy consumption and our energy efficiency on an ongoing basis. In order to achieve these objectives, we are integrating an energy management system, based on standards such as ISO 50001, into our existing quality management system.

Natural gasIn the 2022|23 financial year, we met approximately 66% of our total energy needs around the world with natural gas, 10 % from renewable sources

Supplying ourselves with renewable energyAt a number of our plants, we met some of our energy needs from biogas produced on site.

Continuously improving our specific energy consumptionWe have set ourselves specific targets in the Fruit segment. By 2025|26, the fruit preparation plants (exlcuding primary processing facilities) want to reduced their total energy consumption by 5 % to 1.95 GJ/ tonne of product output. We are currently working on the development of science-based targets.

Water, perhaps the most important resource globally speaking, is used and drained in a sustainable manner at all our sites. We harness the water contained in the agricultural raw materials for use in our processes where possible, as is the case when producing juice concentrate from apples. Water is cleaned and reused time and again. On-site or communal waste water treatment plants ensure that the waste water produced is treated in an environmentally sensitive way in accordance with local regulatory thresholds.

In the area of fruit preparations (excluding primary processing facilities), we want to reduce the amount of water withdrawn by 5 % to 4.24 m³/t of product output by 2025|26.

| Fruit segment | 2022 | 23 |

|---|---|

| Water withdrawn in m3 per tonne of core and by-products | 4.47 |

| Water discharged in m3 per tonne of core and by-products | 4.04 |

| Water consumed in m3 per tonne of core and by-products | 0.43 |

It is our operating principle to maximise the utilisation of agricultural raw materials by making valuable by-products, contributing to our economic and social bottom line.

While the production of fruit preparations generates very little agricultural residue suitable for further use, the press cake from apple juice production, known as apple pomace, is processed into high-quality by-products.

| Fruit segment | 2022 | 23 in tonnes |

|---|---|

| Waste disposed | 25,529 |

| of which hazardous waste | 333 |

| Kilogramme waste per tonne of product | 28.9 kg |

| Gramme hazardous waste per tonne of product | 377 g |

An average of 5,796 employees (headcount) worked in our Fruit segment during the 2022|23 financial year. They are a key factor for success due to their commitment, range of skills, experience and views.

AGRANA endeavours to offer interesting work, opportunities for professional and personal development and training, and a workplace environment in which employees feel integrated, respected and connected.

Non-permanent staff

1,290

59.2 %

Permanent staff

4,131

32.8 %

Blue-collar2,533

23.0 %

White collar1,598

48.3 %

Managers

297

28.6 %

Of which Executive Leadership

11

18.2 %

Total

Female

At the end of the day, it is important that all of our employees return home safely. We strive to achieve this objective by means of regular trainings on safe working processes, implementing best practice cases and providing workplace safety materials as part of our zero-accident policy.

In the 2013|14 financial year, we have started to collect workplace safety data across all business segments by means of uniform worldwide criteria. On the basis of annual evaluations, we have defined individual targets in the area of fruit preparations at present for the coming financial year.

Injury rate 22 | 23(number of accidents/ 100 employees p.a.)

1.0

0.6

1.3

Rate of high-consequence injuries 22 | 23(high-consequence injuries / 100 employees p.a.)

0.2

0.2

0.1

Rate of fatalities 21 | 22(number of fatalities/ 100 employees p.a.)

0.0

0.0

0.0

Total

Female

Male

In the 2021|22 financial year, we revised the AGRANA Code of Conduct, which establishes minimum (social) standards and rules of conduct for all employees around the world.

As part of our membership of SEDEX , which we have had since 2009, our production sites perform a SEDEX self-assessment every year. In order to underpin our commitment, 4-pillar SMETA audits took place at approx. 60 % of fruit preparation and fruit juice concentrate sites. The audit reports can be accessed by SEDEX members on the organisation’s online platform.

The education and training, as well as the personal development, of our employees is important to us. Employees in the Fruit segment completed an average of 19.5 training hours in the 2022|23 financial year. In total, 94 % of employees completed a training course.

In the 2021|22 financial year, AUSTRIA JUICE GmbH updated its sustainability data for the purposes of EcoVadis, the international supplier evaluation platform. It again received Gold recognition.

We use cookies and analysis software to make our website as user-friendly as possible. By clicking on "Accept all", you agree to the use of all cookies. You can change your cookie settings at any time. You can find more information in our privacy policy.

Cookies of this category are necessary for the basic functions of the website and therefore cannot be deactivated.

Cookies in this category enable us to analyze website usage and measure performance.